Matthäi leads the way in modern earthworks at Unterweser

Overview

Used Systems

The challenge

Drone Limitations and Delays

In the construction industry, surveying plays a crucial role in ensuring proper planning and execution. For previous projects, Matthäi relied on drone surveys for tasks like mass volume measurements. Sebastian Ehlers, a surveying specialist at Matthäi, was one of the key people responsible for collecting drone data. He would first have to wait for suitable weather conditions before even traveling to the site. Once there, data could be captured, but it still needed to be processed back at the office before any analysis could take place. Only then could the results be compared with the planned DTM (Digital Terrain Model).

This process was not only dependent on the weather and specialized personnel, but also slow and inefficient often taking several days from the initial request to the final report. As a result, it was too inflexible for daily or even weekly project management

Key Problems:

- Delayed availability of mass and volume data

- Dependence on trained specialist staff

- High manual effort for analysis and reporting

- Limited capabilities for planning and project management

Our Solution

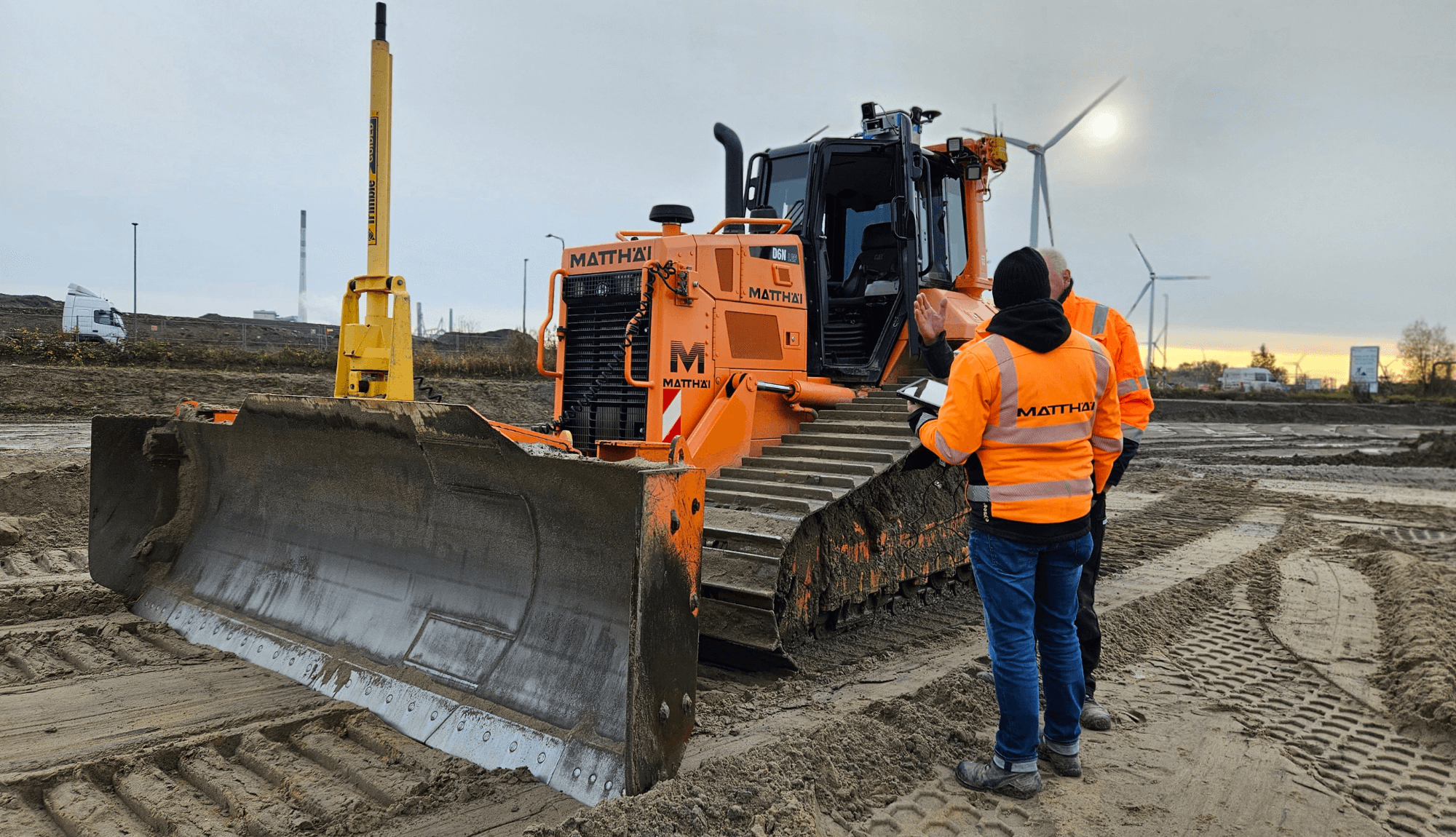

A System that works not only on heavy equipment but also your car

Matthäi made the switch from impractical drone-based data collection to the SDX-Compact system in 2023, significantly improving efficiency and flexibility on site. The SDX-Compact offers all the advantages of drone surveying such as accurate terrain data without the delays, weather dependencies, or specialized personnel. After a short training period, the system could be operated entirely independently. It’s intuitive to use and doesn’t require any surveying background, making it accessible for the entire team.

What makes it even more impressive is its versatility: the system isn’t limited to being mounted on heavy construction machinery. Matthäi successfully uses it even on standard vehicles like a foreman’s car, allowing seamless integration into daily site routines with no added steps or effort.

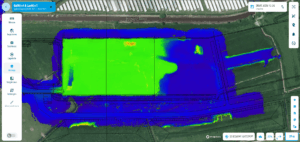

The system has made daily operations at Matthäi more efficient and less stressful by removing the need to manually coordinate survey work. Once activated, it runs autonomously scanning the terrain while the machine or vehicle is in motion. The collected data is automatically uploaded to the SDX-Cloud and becomes available for analysis within minutes.

By minimizing surveying hassles, Matthäi’s team can focus more on critical site operations. Project managers can easily compare current conditions with planned data (such as the DTM) or track progress week by week. This allows for measurable progress tracking and proactive planning of personnel, equipment, and materials. External survey deployments are no longer needed and data capture is now a seamless part of everyday site routines, with no added staff, no delays, nor dependencies.

Customer Feedback

“In the past, we had to rely on the weather and go through complex data evaluation – today, a few minutes of driving is enough to get current terrain data.”

Next Steps

Taking Advantage of Cloud Features

Sodex proved its value to Matthäi by handling the complexity and scale of such a large construction site. With continuous, automated progress tracking, the system sets a forward-thinking standard for how earthworks can be managed across future projects. Matthäi now plans to expand its use of features like dashboards, automated volume calculations, and time-based comparisons. The powerful combination of hardware and cloud technology creates a solid foundation for bringing digitalization to everyday construction work.

Before and Now Comparison:

- Surveying

Before: Drone + manual post-processing

Now: Automatic during vehicle movement - Data Availability

Before: around 3 days

Now: within minutes - Personnel Effort

Before: Surveyor + CAD software

Now: Foreman is sufficient - Operation

Before: complex specialized software

Now: simple cloud interface - Planning & Control

Before: delayed and dependent

Now: real-time evaluation

The Result

Benefits Throughout the Whole Process

Advantages at a Glance:

- Autonomous Data Capture: automatically activated through vehicle movement

- Fast Data Availability: point clouds available online within minutes

- Direct Comparison: target/actual analysis via browser using planning data

- Scalable: easily transferable to various construction sites

Results:

- Mass and volume data are immediately available

- Drone flights and manual post-processing eliminated

- Daily and weekly performance reports optimized

- Improved resource management at the site level

Customer Feedback

“We are delighted with the highly constructive and productive collaboration with Sodex and hope to further increase our productivity through digital innovations.”

Turn your heavy machinery into surveying devices.